Take Control of Complex Events with Structure, Strategy, and Digital Precision

Planned shutdowns and turnarounds are among the most resource-intensive events in industrial operations. Whether you're in oil and gas, chemicals, mining, or heavy manufacturing, these critical events offer a rare window to maintain, inspect, upgrade, and futureproof your assets. But they also carry significant risk in the form of lost production, cost overruns, and safety incidents if not tightly managed.

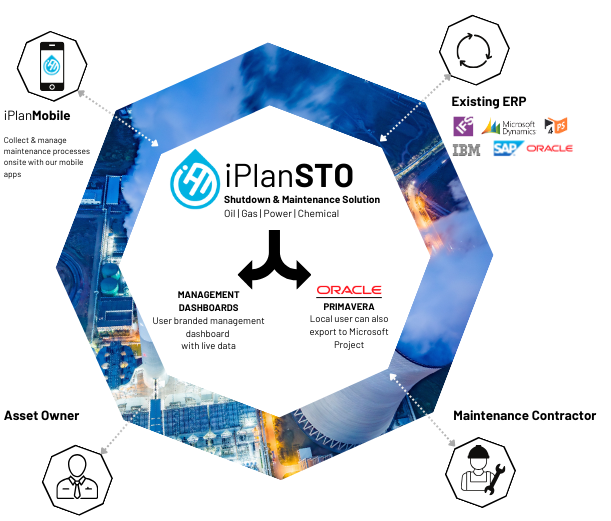

At IAMTech, we’ve helped clients streamline even the most demanding turnarounds using digital tools like iPlanSTO, enabling them to move from reactive firefighting to disciplined, data-driven execution.

In this article, we’ve broken down Shutdown and Turnaround Management into six essential phases to illustrate how applying structure at each stage can unlock real performance gains.

Phase 1: Initiation/Strategy – Aligning Business and Maintenance Goals

The strategic phase defines why, when, and how a shutdown is to be executed. It's about aligning the turnaround schedule with business drivers—market demand, seasonal cycles, regulatory requirements, and equipment condition.

Key goals:

- Define the shutdown interval and optimal duration

- Identify internal vs. external resource requirements

- Align the shutdown with production cycles and capital project windows

- Set governance and reporting frameworks

Common pitfalls:

- No long-term TAR strategy (resulting in reactive planning)

- Misalignment between production, maintenance, and capital project teams

- Lack of clarity around decision-making and responsibilities

- Unaware of other, external events taking place at the same time

IAMTech Tip:

iPlanSTO allows for a holistic approach to be taken for all planned events, ensuring availability of all required resources across your entire portfolio. Utilise iPlanSTO to establish a standardised shutdown framework with predefined workflows, role-based access, and KPI tracking—visible to all in real time.

Phase 2: Scope – Build the Right Worklist

Every hour added to your TAR scope carries a cost. The scope phase is your opportunity to filter work, challenge assumptions, and ensure that only essential tasks are included.

Best practices:

- Apply a risk-based work selection process

- Eliminate low-priority or deferrable work

- Identify work that can be executed pre- or post-shutdown

- Validate all tasks with clear business or compliance justification

Common pitfalls:

- No formal worklist review meetings

- Scope creep from unvetted late additions

- Inconsistent risk evaluation

IAMTech Tip:

With iPlanSTO’s integrated scoping module, teams can manage scope approvals, attach justifications, assess, check, and challenge requests from a multitude of sources and view estimated durations in one digital environment.

Phase 3: Planning – From Worklist to Workpacks

Planning is the bridge between your approved scope and field execution. It’s where tasks become job plans, and where miscommunication (or precision) takes root.

Activities in this phase include:

- Pre-shutdown inspections and field verification

- Defining job steps, required resources, and safety measures

- Pre-ordering materials and scheduling external services

- Creating workpacks with permits, drawings, and procedures

IAMTech Tip:

iPlanSTO can automatically generate your workpacks , improving clarity and reducing duplication. Real-time feedback loops allow planners to learn and improve job plans with every TAR. With iPlanSTO you can scope tasks from anywhere; remotely, in an office via iPlanSTO desktop or out in the field using iPlanMobile.

Phase 4: Scheduling – Managing Time with Accuracy

A well-sequenced schedule is key to controlling downtime and resource utilisation. The scheduling phase integrates work from all disciplines—maintenance, engineering, operations, and contractors—into a single executable plan.

Must-haves:

- A unified master schedule

- Task sequencing based on critical path logic

- Resource levelling across departments

- Defined cut-off date for scope additions

Common missteps:

- Overlapping tasks from different teams

- Forgotten prep tasks like LOTO, hot bolting or access

- Lack of buffer for delays or rework

IAMTech Tip:

Use iPlanSTO to populate your turnaround scheduling software, our solution generates all of the necessary planning data to populate Primavera P6, MS Project, Excel etc. iPlanSTO can generate XML, structured to work with your existing scheduling tool, ensuring key data such as: resources, durations, start dates, finish dates & logic links are available. This data can be bidirectionally linked enabling it to be passed back and forth as required. iPlanSTO’s integrated scheduler visualises task dependencies, identifies conflicts, and makes real-time adjustments. Lock in a work addition cutoff and enforce it digitally with automated approvals. iPlanSTO includes preloaded norms for estimating shutdown activities, from electrical to mechanical and more. You can also upload your own norms to fine-tune the software to your specific needs. Watch this video to learn more.

Phase 5: Execution – Coordinated, Real-Time Delivery

This is where your planning gets put to the test. Execution is about visibility, control, and the ability to adapt quickly to changing conditions on the ground.

Execution success factors:

- Clear command structure with daily review cycles

- Real-time progress tracking by area, contractor, and task

- QA/QC checks integrated into job workflows

- Agile response to unexpected issues

IAMTech Tip:

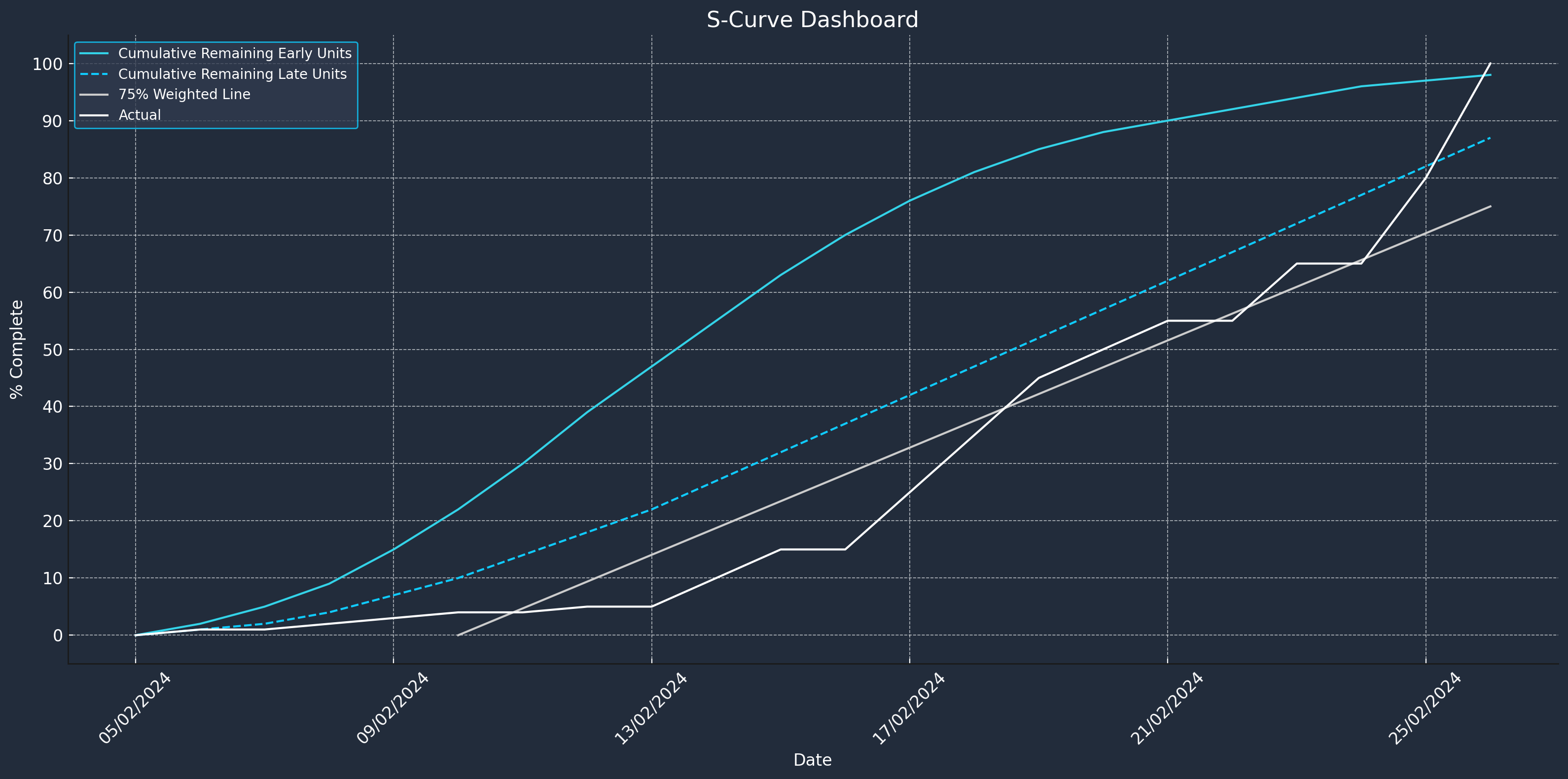

iPlanSTO’s built in dashboards and reports, including the S-Curve, provide Turnaround Teams with real-time information, enabling stakeholders to see percent-complete, resource performance, and budget consumption in real time and make timely and accurate decisions.

Phase 6: Closeout & Critique – Learn, Improve, Repeat

The final phase is often skipped or rushed, but it’s where real turnaround optimisation happens. Every shutdown provides insights that can reduce cost and downtime on your next event.

Closeout activities:

- Capture lessons learned from all teams

- Measure performance against original KPIs

- Review contractor performance and issue resolution times

- Archive documentation for audits and future planning

IAMTech Tip:

With iPlanSTO, your entire TAR lifecycle is captured and reportable. Use closeout reports to feed into future shutdown planning—ensuring you don’t make the same mistake twice. iPlanSTO’s brand new completions module will track and verify that all planned work during a shutdown or turnaround is fully completed, inspected, and approved before assets return to operation. It includes tools for punch list management, system handover tracking, progress monitoring, and documentation control, ensuring a safe, structured, and auditable transition from maintenance to operational status.

Final Thoughts

Shutdowns and turnarounds are critical opportunities, not just costly interruptions. With a structured six-phase approach and the right digital tools, you can turn TARs into a competitive advantage.

Ready to optimise your next shutdown?

Talk to us or book a live demo of iPlanSTO to see how it works in your environment.